Originally published 2018 in the Atlantic Daily Bulletin.

During our British Titanic Convention at the White Swan Hotel this year, our BTS Treasurer John Creamer, asked me if I would consider producing a memorial wall plaque for the Titanic Crew Memorial Window in St Marys church Southampton.

The plaque had to be designed, produced and installed in the church before the Service of Dedication by the Bishop of Winchester, the Right Reverend Tim Dakin,on Sunday the 27thof May.

This gave me a working time scale of around 4 weeks which sounds a long time but when you consider there had to be number of designs produced for consideration, source the materials and get everything OK’d, produced and installed it was a tight schedule.

The Plan

a) The original idea was to make the memorial wall plaque using materials that would create a direct and emotive link between the plaque and the Titanic Crew Memorial Window itself.

b) We wondered if it was possible to source enough useable brass from S.S. Olympic and use this to produce the brass plaque.

c) We also wanted to source enough original wood from S.S. Olympic to make the plinth that the brass plaque would sit on.

d) Sourcing that amount of original brass from S.S. Olympic was over ambitious and was just not possible in the time scale we had to work with. We therefore had to revert to the choice of new brass.

e) However, sourcing original wood from S.S. Olympic was more successful, after a visit to White Star Memories John White and David Scott-Beddardwere able to supply a quantity of original wood from the Olympic that would enable me to make the wooden plinth on which the brass plaque would sit.

The Wall Plaque Designs

a) Seven different concept designs were created for the wall plaque and laminated mock-ups were made of each design.

b) I took all of these to St Marys church and placed each mock-up, one by one, on the wall by the Titanic Crew Window.

c) Each mock-up was placed in a number of different locations on the wall and photographed.

d) The purpose was to give the church the choice of a number of plaque designs and locations so they could decide which design was to be used and where it was to be placed on the wall.

e) All the photos and information was submitted to the church for their consideration and decision and from this a design and location were chosen by the church.

The Plans

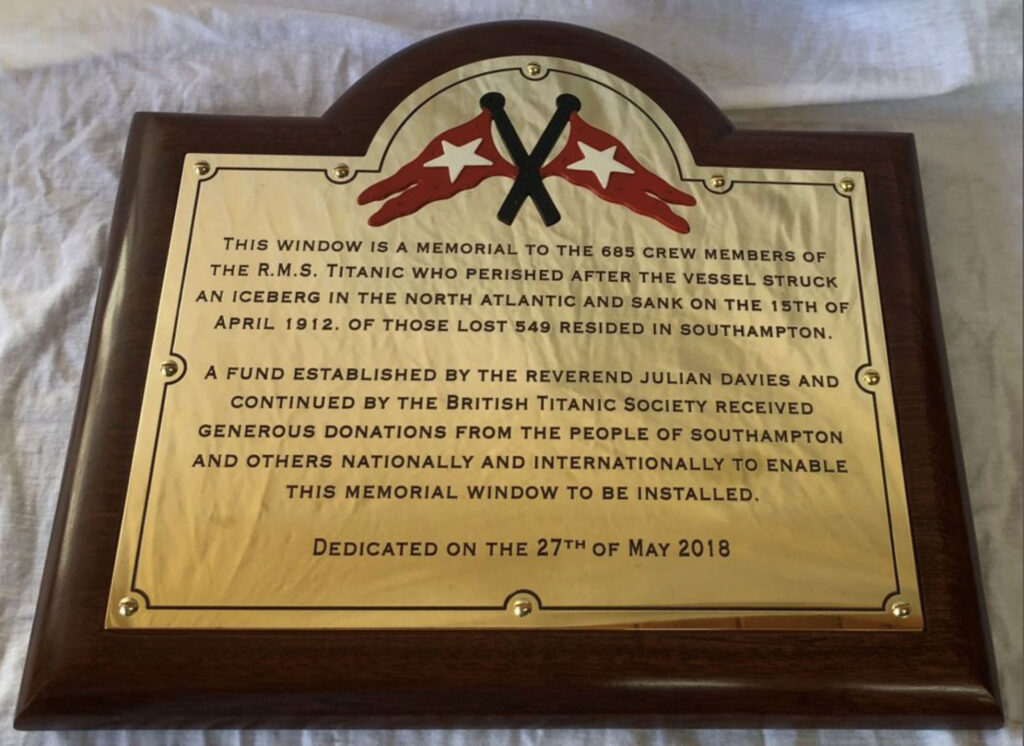

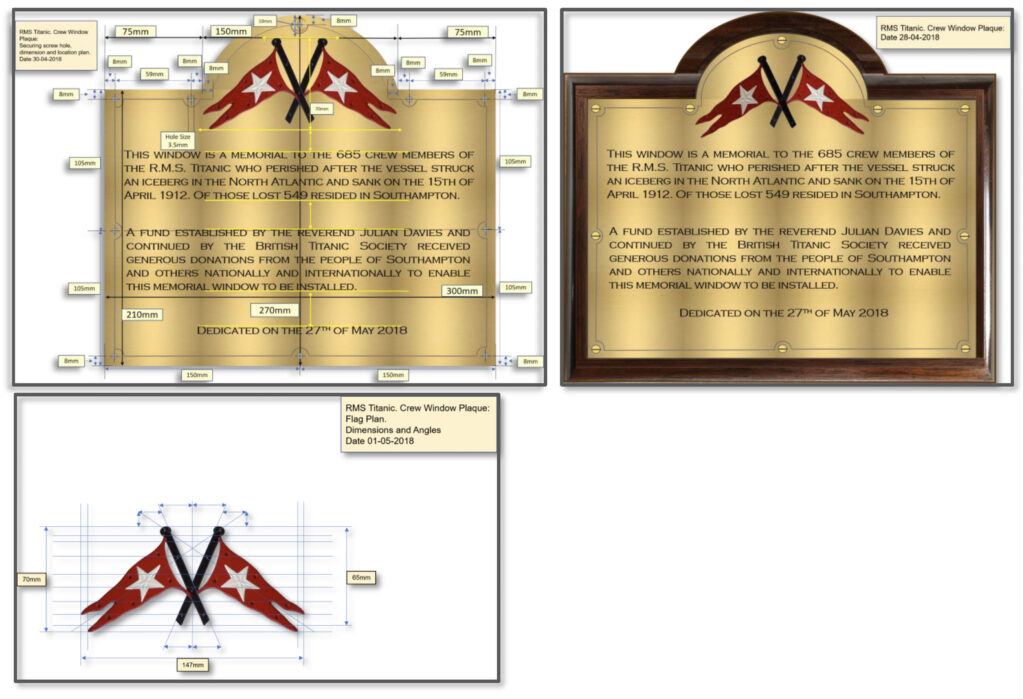

a) Once the final concept was decided upon a total a number of 10 tech drawings were produced to cover all aspects of the plaque and plinth production and 3 of these are shown below.

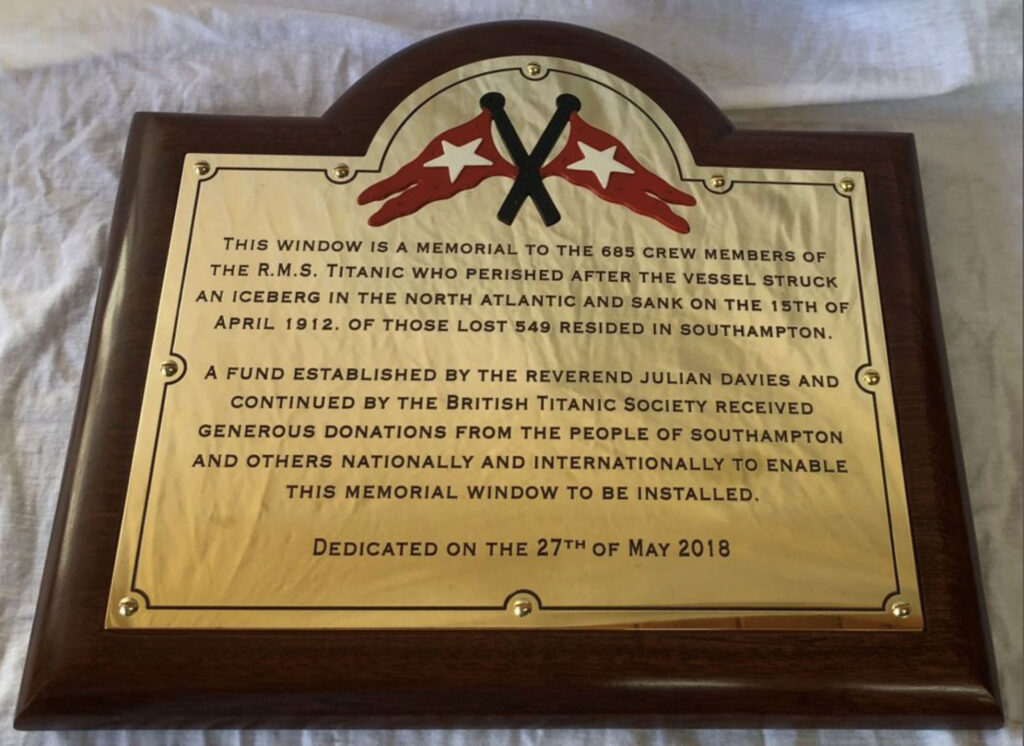

b) The design of the brass plaque incorporated the required text, cosmetic design lines, fixing holes and two small crossed White Star Line flags. The flags were hand made in brass, coloured in enamel and attached to the plaque with miniature machine screws.

c) The content of the text was a collaboration between the church and John Creamer.

The Plaque Production

a) Following the design plans the brass plaque was shaped, engraved with text and design lines, infilled in black, drilled with the fixing holes and polished.

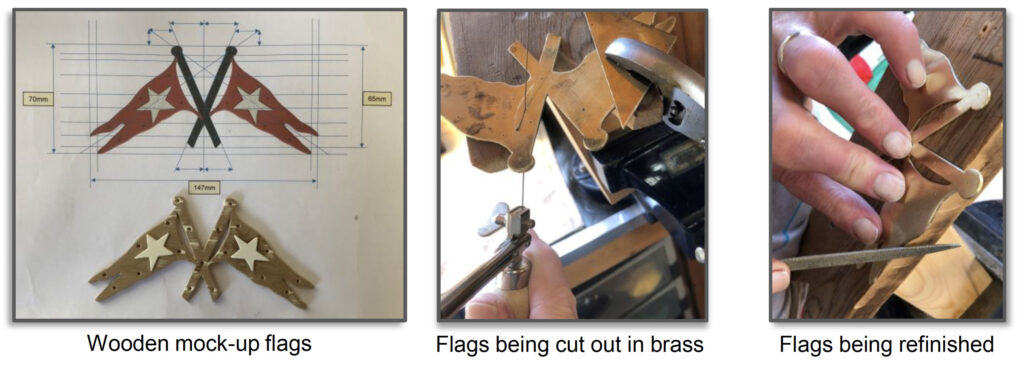

b) The small White Star Line flags were first produced as a wooden mock-up to confirm production technique, dimensions and angles, once done the flags were then produced in brass.

The Plinth Production

a) The wood we had from S.S. Olympic was not of a dimension that would accommodate the brass plaque in its height.

b) We therefore had to resize the wood sample and create a join in it.

c) The wood was prepared by removing all visible nails, screws and paint. The wood was then checked with a metal detector to make sure there were no nails or metal objects hidden under the surface that could damage the machine to be used in the next procedure.

d) The wood was the put through a “thicknesser” to remove the lightest possible skim off each surface. This is done to create a flat, even surface to work with.

e) The wood was then divided into two sections and the edges machined to create a flat edge surface.

f) The wood was then bonded together at these flat edges to produce a piece that would be dimensionally suitable to accommodate the brass plaque.

g) The piece was then machined and shaped to the plinth design drawing. Four mounting feet were produced also using the wood from S.S. Olympic.

h) The plinth was then fine sanded smooth, refinished, sealed, stained and French polished.

i) We put a recess into the plinth and this area will be covered by the brass plaque when its assembled on the wall.

Within this recess we placed a message explaining how the plaque was made and the names of those involved in its production. This was done so that if, many years into the future, the plaque disassembled for restoration the restorer will find the message explaining its manufacture and who was involved.

The “Titanic Crew Window” Memorial Plaque

a) The completed plaque was installed on the right hand wall next to the Titanic Crew Window in St Mary’s church.

b) Drilling holes into a very old church wall was a little nerve racking and in fact I kept all the drilling material from the four holes just in case the plaque ever needs moving. With this original material we can create an accurate filler mix to fill up the holes if required.

Conclusion

It was a great honour to be asked to design and produce this memorial plaque for The Titanic Crew Window in St Mary’s church.

It was a huge project that had a short working time scale for its concept, design, production and installation.

The use of materials from S.S. Olympic in its production was very important so we could not only be informative about the “Titanic Crew Window” but create an additional and very important emotive connection between the window and the plaque itself.

The church could have gone to a conventional “High Street” company and had a plaque produced but I feel that the bespoke end result we have achieved by the people involved would have been difficult to equal from an outside company.

The production of the plaque was the result of collaborated by a number of people and they are;

John Creamer. David Scott-Beddard. Nikki Allen. Brian Taylor. Mary White (St Mary’s Church Warden). Susan Angel. Mick Evans (Engraver). John White (White Star Memories). Steve Rogers (A. Rogers & Sons).